In a world where technology is rapidly advancing, laser-cutting machines have become an essential tool for many businesses. With its precise and versatile capabilities, these devices can be used to create intricate designs with accuracy and ease.

This article explores the advantages of using laser-cutting machines in terms of precision and profitability. We will discuss the different applications of this technology as well as how it can help improve productivity while lowering production costs. By understanding the potential benefits that come with utilizing this machinery, we hope to demonstrate why so many companies are turning to laser cutters for their production needs.

Advantages of Using a Laser Cutter for Precision and Profit

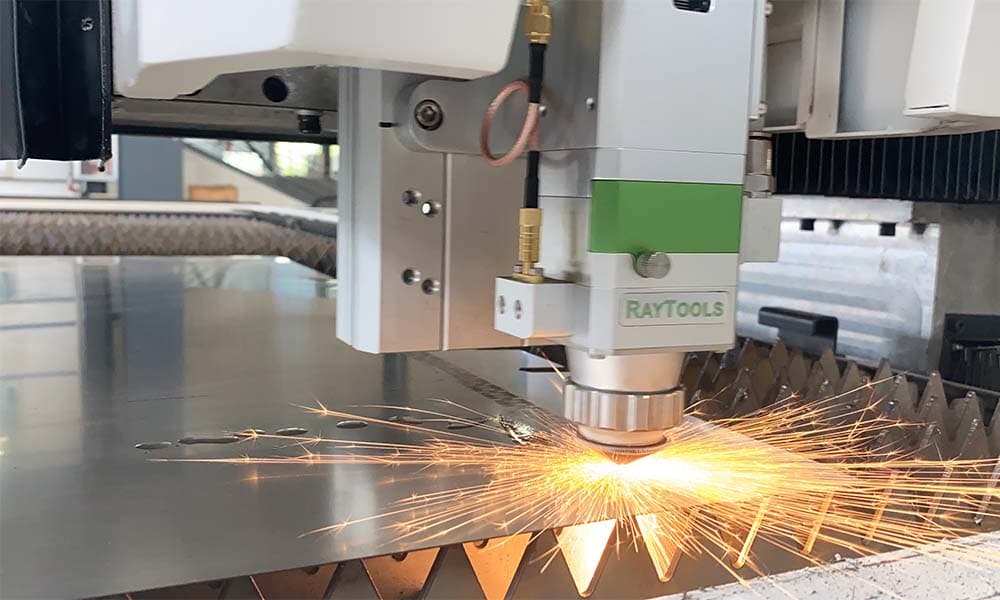

Laser-cutting machines offer a wide range of advantages for precision and profit. From increased accuracy to faster production times, laser cutters open up many opportunities for businesses looking to maximize efficiency while creating high-quality products. The most obvious advantage is the increased accuracy that comes with using a laser cutter.

Laser cutters can produce highly precise cuts on surfaces such as metal, wood, plastic, or even glass without any warping or distortion in the material being worked on. This allows manufacturers and fabricators to create complex shapes and designs with greater confidence that the end product will meet their exact specifications.

Another major benefit of using a laser cutter is its ability to reduce errors associated with traditional machining techniques like sawing or drilling which often result in misaligned parts, incorrect measurements, or wasted materials due to inaccurate cutting patterns. Using a laser cutter eliminates these issues by precisely guiding the beam along preprogrammed paths so it hits each target spot exactly where it’s supposed to be — resulting in fewer errors and less waste overall.

Finally, one of the key benefits of using a laser cutter over other methods is its speed: lasers can complete jobs much faster than manual tools since they don’t require setup time nor do they need multiple passes over an area like some mechanical processes do. Therefore manufacturers have shorter lead times when producing items with intricate designs; this also means more projects can be completed within tight deadlines without sacrificing quality control – ultimately leading to better profitability for businesses who use them regularly!

Understanding the Versatility of Different Types of Lasers

Laser-cutting machines are invaluable tools in modern manufacturing and production. They offer unparalleled precision while being able to cut a wide variety of materials with ease, making them ideal for businesses that cost-effectively require high-quality results.

Understanding the versatility of different types of lasers is key to getting the most out of laser cutting technology. The type of laser used has an impact on its performance, efficiency, and accuracy when cutting materials such as acrylics, metals, plastics, and fabrics.

For instance, solid-state lasers are powered by electricity which produces infrared light that can be focused down to a small beam for precise cuts on thinner materials like paper or plastic film; CO2 lasers use carbon dioxide as fuel and generate heat energy instead which makes it suitable for thicker materials like wood or metal alloys; finally, there is fiber laser technology which uses pulses of infrared light to quickly cut through even some harder metals like aluminum at speeds faster than any other type due to its intense power output over short periods. Each type also offers distinct advantages depending on the application at hand – from engraving intricate details onto stainless steel panels using ultrafast pulsed UV fibers lasers to slicing up thin sheets into complex shapes thanks to C02s’ higher power output – knowing what you need will help you get the best results possible from your investment in laser cutting technology.

Understanding how each type works will not only ensure accurate cuts but also save time and money since selecting the wrong one could lead to costly delays due to increased cycle times or damaged parts if selected incorrectly!

Exploring Applications for Laser Cutters in Manufacturing and Creative Industries

The increasing prevalence of laser cutters has revolutionized the manufacturing and creative industries. From precision cutting to intricate designs, these machines can do it all.

In this article, we explore how lasers are being used to increase productivity and profit in both industries. Manufacturing is one area that has seen major gains due to laser cutters.

With their ability to precisely cut metal with minimal waste material, they have enabled manufacturers to reduce costs while still producing high-quality parts at a rapid pace. The technology also reduces the need for expensive manual labor, making it more cost-effective than traditional methods without sacrificing accuracy or quality.

Laser cutting machines also allow for quick prototyping of products before full production begins, resulting in significant savings on time and money spent on product development and testing phases. Creative uses for laser cutting machines have exploded over the past few years as well.

Designers are now able to create complex patterns and shapes using materials like wood, acrylics, leather, paper, or fabrics quickly and accurately with just a few clicks of a button – from detailed images etched into jewelry pieces to 3D sculptures made out of cardboard boxes! This technology has opened up new possibilities for artisans who wish to push boundaries when creating unique objects that captivate viewers with their complexity and delicacy – something not easily achievable by other means before now. In conclusion, we can see how versatile laser cutting machines can be in both manufacturing processes as well as creative endeavors – enabling businesses large or small alike to make precise cuts while saving time and money along the way! As such an invaluable tool that will only become more integral within our societies down the line, we look forward to seeing what new heights this technology reaches next!

Benefits & Challenges Associated with Operating a Laser Cutter

The Benefits & Challenges Associated with Operating a Laser Cutter are vast and varied. For businesses looking to expand their capabilities, laser cutters can offer precise cuts with minimal waste or cleanup.

In addition to the accuracy of cut, laser cutting materials can be quickly changed allowing for quick turnaround times that make it an attractive choice for many businesses. However, operating a laser cutter does come with some challenges that must be addressed to ensure consistent results and reliability.

First and foremost is safety; as lasers have the potential to cause serious injury if used incorrectly, operators must take great care when using them. It is also important that all materials being cut are compatible with the machine’s settings to avoid damaging either the material or the machine itself.

Additionally, because of their precision engineering, laser cutters require regular maintenance and calibration to continue performing at their best over time. Overall though, these benefits far outweigh any associated challenges when it comes to utilizing this versatile piece of equipment for commercial purposes.

Not only do they provide accurate cuts but also allow manufacturers more freedom in terms of design possibilities compared to other methods such as milling or jigsawing – making them an invaluable asset for businesses across industries looking towards increased efficiency and profit margins without sacrificing quality control.

Conclusion

Laser Cutting Machines are a versatile and powerful tool that can be invaluable to any business. Not only can they provide precision cutting for a variety of materials, but also have the potential for increased profits.

As the technology continues to improve, Laser Cutting Machines will become an increasingly important asset to businesses large and small as they look for ways to enhance their production capabilities while still maintaining cost-effectiveness. This makes them an essential part of any company’s arsenal when it comes to staying competitive in today’s global marketplace.