The manufacturing industry is going through a revolution, and laser-cutting machines are at the forefront of this transformation. These powerful tools have allowed for an unprecedented level of precision and control when it comes to creating products out of materials like metal, plastic and wood.

From prototyping to mass production, laser cutting machines have enabled manufacturers to bring designs from concept to reality faster than ever before. With their ability to cut intricate shapes with ease, these machines can help create complex works that were previously impossible or far too costly using more traditional methods.

In addition, they offer greater accuracy at lower costs than other forms of machining. This makes them ideal for both rapid prototyping and large-scale projects alike.

The possibilities afforded by these modern tools are almost limitless; in the hands of experienced professionals, there is no limit as to what can be achieved with a laser cutter!

Introduction to Laser Cutting Machines

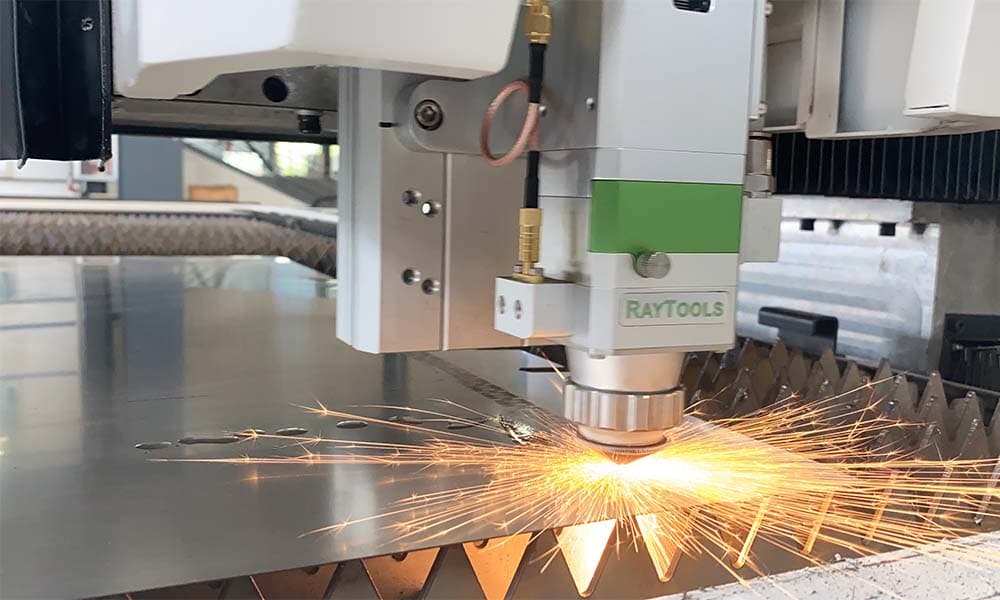

The introduction of laser-cutting machines has revolutionized the manufacturing process, allowing for greater precision and accuracy than ever before. Laser-cutting machines use a high-powered beam of light to cut through materials with ease, making them an invaluable tool in many industries.

With laser cutting technology, manufacturers can create intricate designs that wouldn’t be possible with traditional methods. This guide will provide an overview of how laser cutting works and the advantages it provides for modern manufacturing processes. Well also look at some examples of products created using this technology and discuss the future potential applications of this groundbreaking technology.

The Benefits of Laser Cutting Technology

Laser-cutting technology has revolutionized the manufacturing industry, allowing companies to create complex designs with precision and speed. One of the major benefits of laser cutting is that it can produce extremely detailed pieces using intricate patterns. This makes it perfect for creating parts for complex machines or components with very specific requirements.

Additionally, laser cutters are also able to quickly and easily cut through thicker materials such as metals and composites which allows manufacturers to take on projects that previously weren’t possible due to time constraints or cost issues. Moreover, laser cutters also require less manual labor than traditional methods like sawing, drilling or milling because they are computer controlled so there is no need for operators in most cases.

The machine does all the work itself so it saves time and money on training personnel too. Furthermore, since lasers deliver a precise cut without introducing extra heat into the material being worked on they don’t cause any warping or distortion either – something that can be incredibly difficult when working with other tools like grinders or drills.

How Laser Cutters Revolutionize Manufacturing

Laser cutters have revolutionized the manufacturing industry, allowing for faster and more precise production than ever before. By using a laser beam to cut through materials, manufacturers can create products with intricate designs that would otherwise be impossible or too time-consuming to achieve.

Laser-cutting machines are also capable of producing parts in bulk much quicker than traditional methods, making them an ideal solution for large-scale projects. With their ability to accurately replicate complex shapes and patterns, these tools are invaluable when it comes to creating customized items such as jewelry or medical instruments. Moreover, lasers can be used on a wide variety of materials, including plastics and metals, giving manufacturers greater flexibility when creating prototypes or final products.

The cost savings associated with using laser cutting machines also make them attractive options in comparison to manual labor for many applications. In short, laser cutters provide immense benefits over conventional manufacturing techniques by significantly increasing speed and accuracy while reducing costs – truly revolutionizing the industry!

Conclusion

The revolutionizing of manufacturing with Laser Cutting Machines has enabled a more efficient and cost-effective process for producing products. This technology has been instrumental in the rapid development of many industries by taking design from concept to reality quickly and accurately.

The ability to precisely cut intricate shapes which would otherwise be impossible or too time-consuming using traditional methods makes laser cutting machines invaluable tools in the production process, ensuring consistent quality while streamlining costs. With its unparalleled speed, precision, and affordability, it is no wonder that laser-cutting technology is quickly becoming an industry standard across multiple sectors.