In the age of modern technology, ensuring product reliability is essential for businesses to remain competitive. To ensure that products can handle extreme conditions without being damaged or failing performance tests, companies are utilizing thermal shock chambers.

Thermal shock chambers rapidly shift between hot and cold temperatures to simulate various environmental stressors on a product, such as rain, hail, and snow. By simulating these conditions with thermal shock chambers, businesses gain insight into how their products will perform in real-world applications.

In this article, we will explore how companies use thermal shock chambers to guarantee product reliability when subjected to harsh environments.

Understanding the Effects of Temperature Extremes

Temperature extremes can have a profound impact on the reliability of products. By exposing them to extreme temperatures, manufacturers can determine a product’s durability and ensure compliance with industry standards and regulations.

Thermal shock chambers are designed to recreate these conditions safely and accurately to test the effects of temperature extremes. The chamber can rapidly cycle between hot and cold temperatures, often up to 100°C (212°F), allowing engineers to observe how their products handle such changes over time.

With thermal shock testing, manufacturers can understand how their products will perform in real-world situations when exposed to dramatic temperature shifts. This helps identify any weaknesses that could cause catastrophic failure or malfunction under certain circumstances before they occur in actual use cases.

Additionally, this type of testing also provides valuable data for research & development teams looking for ways to make their designs more resilient against fluctuations in external environmental conditions. Ultimately, understanding the effects of temperature extremes through thermal shock chambers allows companies from numerous industries to create safer and more reliable products for consumers worldwide.

How Thermal Shock Chambers Work

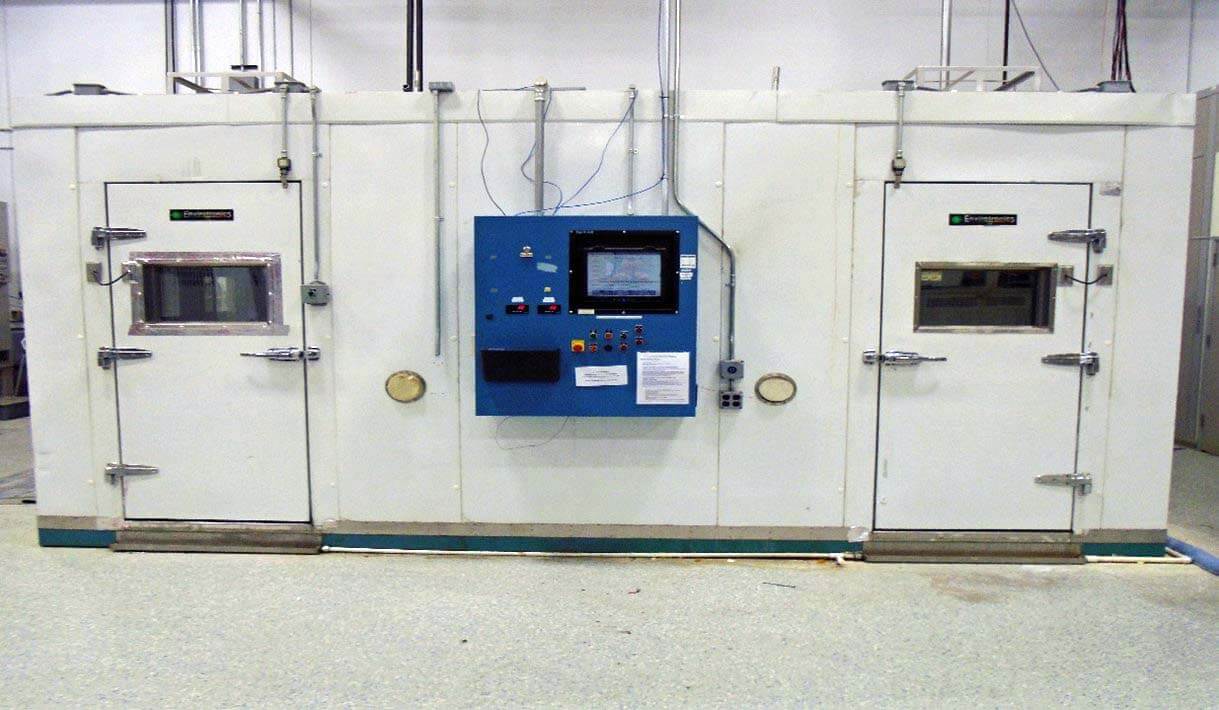

Thermal shock chambers are designed to simulate extreme temperature changes to test the reliability of products. This is done by rapidly cooling a product from one extreme temperature and then heating it to another, allowing manufacturers to gauge its performance under varying conditions.

These chambers can also be used for testing items such as circuit boards or medical equipment that need to withstand sudden changes in temperature without being damaged. For these tests to be successful, thermal shock chambers must accurately replicate both hot and cold temperatures, while minimizing the amount of time required for the process.

In doing so, they ensure that products remain reliable during any kind of weather condition or environment they might encounter.

The Benefits of Thermal Shock Testing

Thermal shock testing is a powerful tool for ensuring product reliability. It simulates the effect of extreme temperatures and rapid changes between them, providing manufacturers with valuable insight into how their products will perform when exposed to real-world conditions.

The benefits of thermal shock testing are clear: it can reveal any flaws or weaknesses in the design of a product before it reaches the customer, reducing costly recalls and improving customer satisfaction. Companies also benefit from increased confidence that their products will be reliable even under harsh environmental conditions such as extremes of hot and cold weather, high humidity levels, or sudden temperature fluctuations.

Additionally, thermal shock testing helps identify materials capable of withstanding extreme temperatures without damage – an essential component for industries dealing with hazardous materials or those whose products must operate reliably in challenging environments. By assessing potential failures caused by temperature change, these companies can develop better designs that meet safety requirements while achieving operational efficiency goals. Finally, thanks to advances in technology over recent years, today’s thermal shock chambers are more accurate than ever before – allowing manufacturers to test rapidly changing temperatures while controlling the intensity and rate at which they occur.

This level of precision allows for detailed analysis that could not have been previously achieved — giving manufacturers greater control over their production processes and resulting products’ performance quality.

Challenges in Designing and Operating a Thermal Shock Chamber

Designing and operating a thermal shock chamber presents unique challenges. The ability to accurately control the temperature changes in a thermal shock test environment is essential for ensuring product reliability.

In addition, engineers must be able to accurately monitor and record temperatures during testing conditions. Safety concerns also arise when designing and operating a thermal shock chamber; extreme heat or cold can pose serious hazards to personnel working within the chamber as well as those outside its walls.

As such, proper safety protocols must be followed when designing and operating a thermal shock chamber, including setting up appropriate warning systems should temperatures exceed established limits. Maintaining precise temperature changes in an uncontrolled environment requires careful planning by engineers who must account for various factors beyond simply controlling room temperature, such as air circulation within the chamber and allowable humidity levels.

Finally, because of the nature of these tests – extreme transitions between hot and cold at high speeds – significant stress on products being tested may occur which necessitates careful monitoring throughout each test cycle.

Conclusion

Thermal Shock Chambers are an invaluable asset in the world of product reliability. They provide a safe and effective way to ensure that products can withstand extreme temperature changes, making them highly reliable even in harsh environments.

The chambers provide unparalleled protection from thermal shock, allowing companies to produce long-lasting and reliable products without fear of failure due to rapid temperature shifts. With Thermal Shock Chambers, companies can rest assured that their products will be able to withstand any extreme conditions they may encounter during their lifetime.